![PACS closeup]() Clean Sweep AC

Clean Sweep AC

Pluggage Problem Solver & Material Flow Aid

Those who devote their time and skill to bulk material handling know how much they depend on a material flow that isn’t slowed by pluggage and build-up. This becomes particularly true if you’re working with wet or sticky material such as sand or cement.

Consistent production and customer service require that chutes, bins, hoppers, silos, and bunkers be free of obstruction. Achieving this flow is the ideal – as well as the challenge.

When the material flow slows or backs up, you must spend valuable labor and time correcting the problem. On top of that, pluggage and build-up often waste products and raise the risk of equipment damage. Personal safety can become an issue as well.

At many plants, operators may use pneumatic vibrators for stuck material, but this too can crack system components. Industrial air cannons (air blasters) might also break accumulation with straight, powerful bursts. However, industrial air cannons don’t stop build-up from forming again; they only deal with the issue as it arises.

As your partner in better bulk material handling, Benetech addresses what stands in the way of more profitable production and service. We know what you’re up against with material build-up, and we develop the bulk material flow aids you need to resolve it.

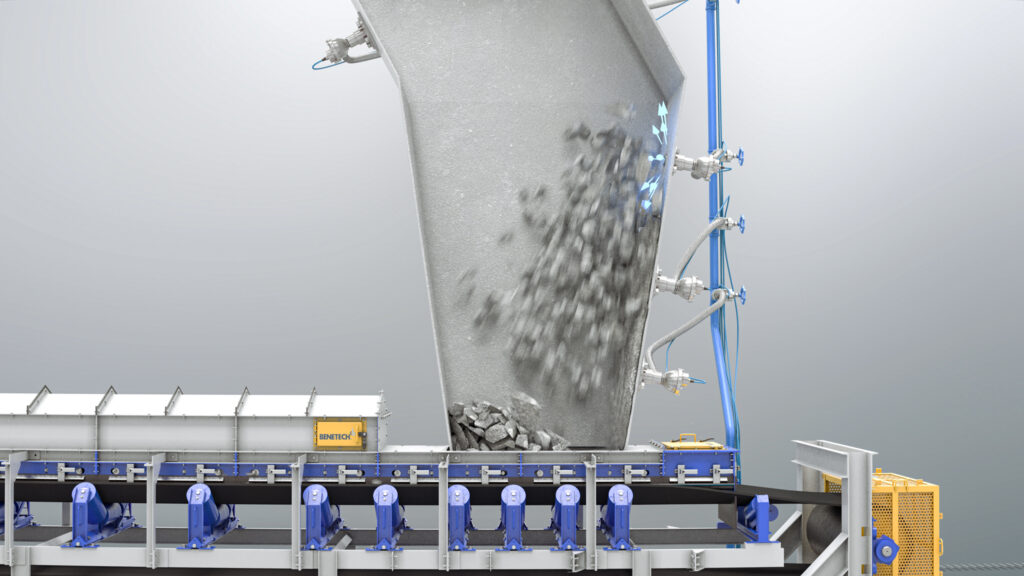

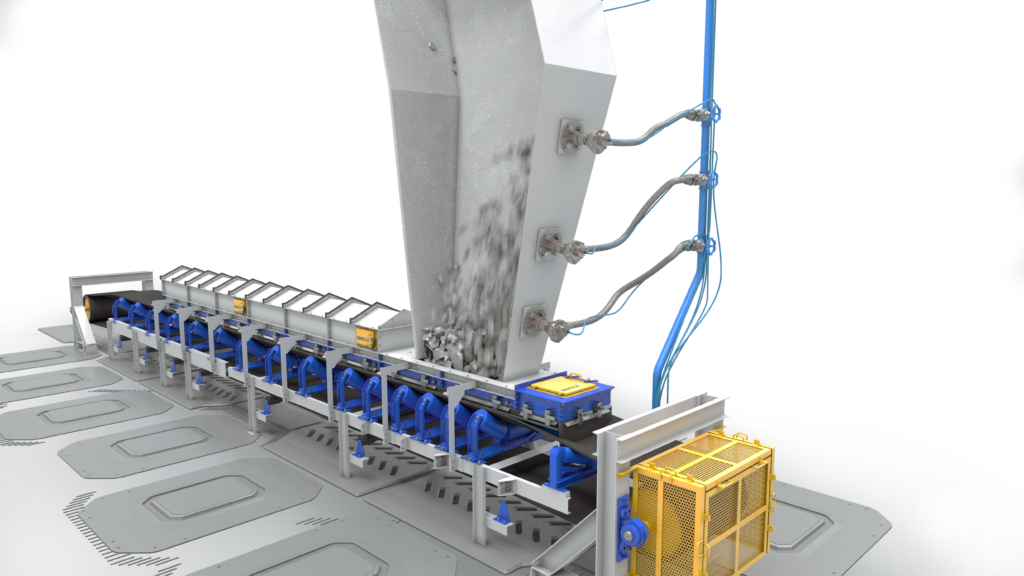

Benetech Clean Sweep (AC) Air Cannon System

Benetech understands how to keep your material flowing because our engineers have researched, designed, tested, and applied the solution.

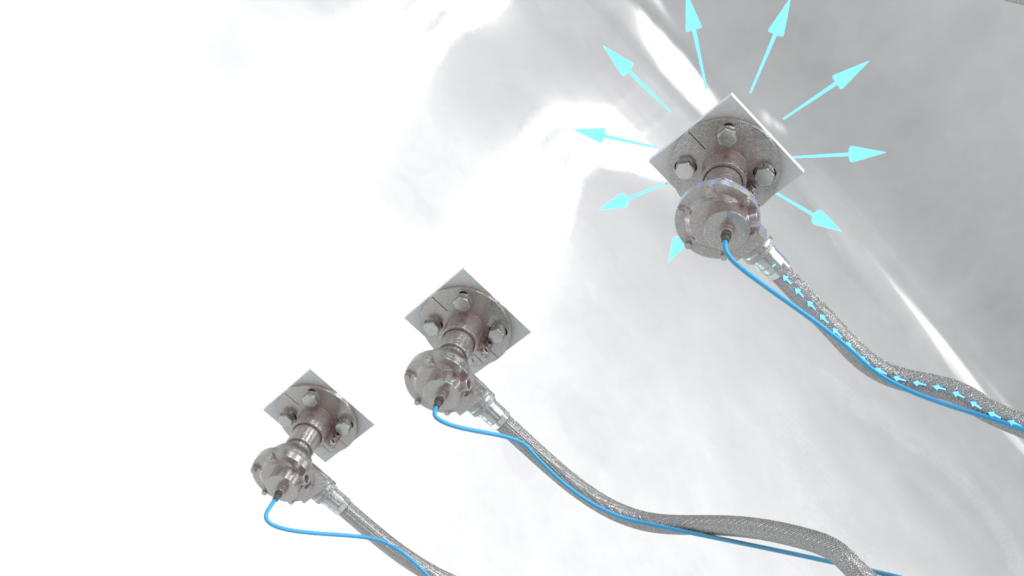

The Benetech pneumatic air cannons use an automatic radial system with standard plant compressed air at 80–100 PSIG to clear pluggage and build-up. Unlike industrial air cannons, which don’t prevent build-up, Clean Sweep keeps your chutes, bins, hoppers, silos, and bunkers clean by not letting material clump and stick in the first place.

We remove existing vibrators and install precisely positioned pneumatic-cannon air nozzles on the sidewall to implement your system. From there, Clean Sweep does everything for you without the need for constant checkups – just let the system run.

Electronic controls trigger each wear-resistant nozzle to fire a precise burst of plant air at 360° for 0.1 seconds along the wall surface through a solenoid valve in a set sequence. The airburst hits the wall at an adjustable distance of two to three feet in diameter. Because the air moves in circles, the material cannot layer on the wall, and gravity carries constantly dislodged product back into the flow.

Beyond its highly efficient function, Clean Sweep offers your plant great convenience of operation and maintenance. Both the control station and the air tank are remote at ground level for easy access. You can also locate the control panel and the timers for user-friendly air pressure and air-release sequencing adjustment. Clean Sweep even auto-cleans itself.

The bulk material flow aids do not require confined-space permits. In addition, because Clean Sweep frees personnel from climbing into containers or under unloading ports to deal with material build-up, it helps make your plant safer.

Benetech air cannons serve as reliable, powerful production assets for many bulk material industries such as cement, steel, coal, aggregate, sand, pet coke, mining, and wood chips.

Benetech Pneumatic Clean Sweep Air Cannons: More Business Benefits

In addition to resolving your immediate challenges with material pluggage and build-up, Clean Sweep provides you with Benetech’s skilled and attentive customer support.

Our field techs are highly trained to install and maintain your pneumatic cannon system onsite at your plant. With vast programming experience, our engineers can customize the system controls for each of your applications. They can also integrate Clean Sweep into a Distributed Control System and write programs to your requirements.

Break Up Production Obstructions Starting Now

The Benetech Pneumatic Air Cannon System contributes to a more efficient, profitable, and hazard-free bulk material–handling business. Increase safety and efficiency while prolonging the life of the equipment. Contact us at (630) 844-1300 today to speak with a Benetech specialist.

Posted in Material Flow, and Material Handling