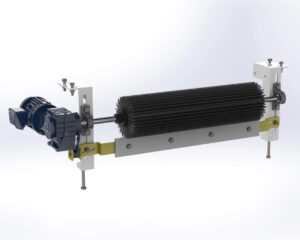

The Benetech Motorized Brush Cleaner

The material build-up in the conveyor system can be a challenge for any bulk material handler. Limiting and controlling the build-up requires the right strategy with the proper equipment.

A brush cleaner is effective at sweeping fines and residue from non-flat conveyor belts such as grooved, ribbed, cleated, and chevron belts.

The conveyor brush is typically mounted near the head pulley on the return side of the belt and connected to a gearbox and motor that allow it to rotate steadily. The large bristles weave in and out of troughs and up and down the belt’s raised sections without getting caught on the belt. Thus, the brush does not damage the belt but instead helps to preserve it.

By reducing build-up on the conveyor after material discharge, the conveyor belt cleaning brush contributes to less lost material, better dust management, and less strain on components such as pulleys and idlers. This adds to better production, less housekeeping and maintenance, and greater plant compliance and safety.

Conveyor brushes can be used with any bulk product, including wet, sticky, abrasive, and static-charged materials. However, they can be especially effective with dry, granular materials such as salt, cement, fertilizer, wood chips, and mineral sands.

Brush Cleaners: Effectively Removing Build-Up from Belts

Constantly aware of your production goals and challenges, Benetech’s engineers focus on the vital facets of eliminating carryback and keeping conveyor belts clean. We understand what your plant might contend with when using a grooved, ribbed, or chevron conveyor belt or any other without a flat surface.

We created our Motorized Brush Cleaner to prevent fine and residual material from clinging to the belt and becoming trapped in recessed areas that standard blade-type cleaners cannot reach.

Mounted to a vertical or horizontal surface, the Motorized Brush Cleaner features rubber bristles that remove fines and residue even in the most hard-to-reach areas. Benetech’s conveyor belt cleaners brush also works only when the belt is moving. To ensure optimal cleaning, the motor turns the cleaner opposite the belt direction as well.

The conveyor brush’s assembly as either a left- or right-hand unit with no part requirements allows it to be installed easily anywhere on the conveyor’s return side. However, it is most commonly placed where the belt leaves its contact with the drive pulley. This keeps the removed material in the transfer point chute work’s dribble chute area to re-enter the material flow.

Space restrictions do not create an obstacle. The brush cleaner can be placed where limited room makes scrapers and spray bars challenging to install and maintain.

Our in-line drive shaft and cleaner bar design provide easier sealing when the brush cleaner is installed in an enclosure. The cleaner bar also makes the assembly self-cleaning, and brush replacements are simple.

The Benetech Motorized Brush Cleaner: Find Out More Today

Benetech believes in one thing: making your operation the cleanest, safest and most efficient, and profitable it can be. We know what you need to reach your highest output because we are of and for your industry. So let’s further discuss how our brush cleaner can keep your conveyor belt moving and your material flowing. Contact us at (630) 844-1300 to speak with a Benetech specialist.

Posted in Conveyor Belt Cleaners